SAM PLASTIC ENGINEERING

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SAM PLASTIC ENGINEERING

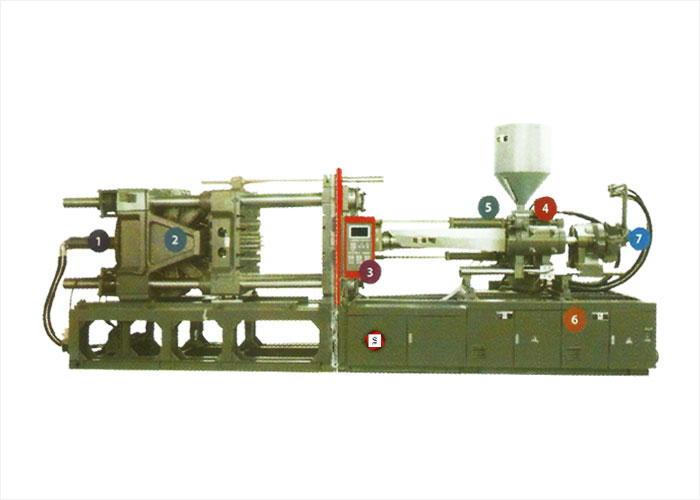

Injection Moulding Machine

ADVANTAGES TO THE CUSTOMER

Significant reduction in energy consumption and therefore energy costs.

Excellent regulations characteristics.

Integrated closed - loop control in converter, compensation for hydraulic non – linearities.

Higher efficiency than a controller asynchronous motor with variable pump.

Amortization of higher initial costs for Servo is offset by power saving within a year.

Less heat entering the system, thus requiring a smaller cooling system.

Lower noise levels.

Reduced spending on hydraulic oil due to smaller oil reservoir.

Increased life span of system oil.

OPTIONAL

Screw Options

- PET Screw

- Bi – Metallic Screw

- PVC Screw

- Uses Vector Control for maximum dynamic

- response.

- With response time of 125us, it makes motor

- response faster.

Other Optional Features

- Additional Core / Unscrew Function.

- Hopper Magnet.

- Robot Interface.

- Accumulator Assisted Injection.

- Vision System For The Mould Safety.

- T-Slot Platens.

- Fly Ejector.

- Synchronous Operation Of Refilling And Mould Open / Close And Ejector Function.

- Tonnage Display.

- RPM Display.

- Auto Gate Open Function In Semi Automatic Mode Assisted With Safety Feature Of Light Curtain.

AUXILIARY EQUIPMENTS – AVAILABLE, EX STOCK

Clamping

- Optimized 5 point toggle design for accuracy, smooth platen movement and equal distribution of clamping force.

- 5 stage programmable opening / closing speeds for ease of control.

- Hydro motor assisted mould height adjustment system.

- Programmable multi stage and pressure controlled ejector system.

- Linear transducer for platen and ejector movement.

- Low pressure mould safety.

- Automated lubrication system.

Injection

- 6 stage injection and hold on function.

- 3 stage plasticizing / charge speed control.

- Auto PID adjust for barrel temperature.

- High plasticizing capacity screw design.

- Pre and post charge suck back function.

- Cold screw protection.

- Insulator barrel heater.

- 5 star radial piston high torque hydro motor.

Controller

- PLC with 8.4” COLOUR LCD screen with alpha numeric keypad.

- HMI with USB for data resort and back up function.

- Password and data lock key protected keypad to prevent tampering.

- Fast setting page shows bird eye view of machine operation.

- Hot Keys to frequently used pages.

- 120 mould data storage.

- Parameter monitoring for last 100 cycles.

- Alarm alert, record and diagnostic function.

- Temperature and injection graph monitors.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.